Mit-ivy ʻoihana metala ʻo Advanced Acrylic Latex Sealing Primer me ka mana penetrating maikaʻi loa

Palapala noi

He maikaʻi loa ia i nā substrates kila a me nā primers hoʻokumu wai, a me nā waiwai kino a me nā mīkini ma hope o ka hoʻomaloʻo ʻana o ka nalu pena.

5. ʻO ka mālama kiʻi ʻoniʻoni pena maikaʻi loa a me ka mālama kala ʻana ma hope o ka hoʻomaloʻo ʻana.

Paipai ʻia ka noi He kūpono ia no ka pale ʻana o ka waikahe o nā kalaka, nā ʻāpana mīkini, nā pono hana ʻenehana, a me nā mea ʻē aʻe e koi ʻia ai ka pale kiʻekiʻe

ʻIkepili ʻikepili kala like ʻole

Kahi maloʻo (50% miscibility) 15 ℃ C <1h ; 25'C <0.5h

Paʻa maloʻo (50% humuhū) 15'C <48h; 25 ° C <24h

Nā Hits "kg.cm" 50

ʻO ka wai (50 ± 5μm) ʻaʻole puhi ke kiʻi ʻoniʻoni 72h, ʻaʻole e kōkua i ka hāʻule, ʻaʻole ka popo.

Paakiki 0.3 (pāpālua pendulum) mīkini waiwai hoʻāʻo ʻoniʻoni mānoanoa (23 ± 3jμm)

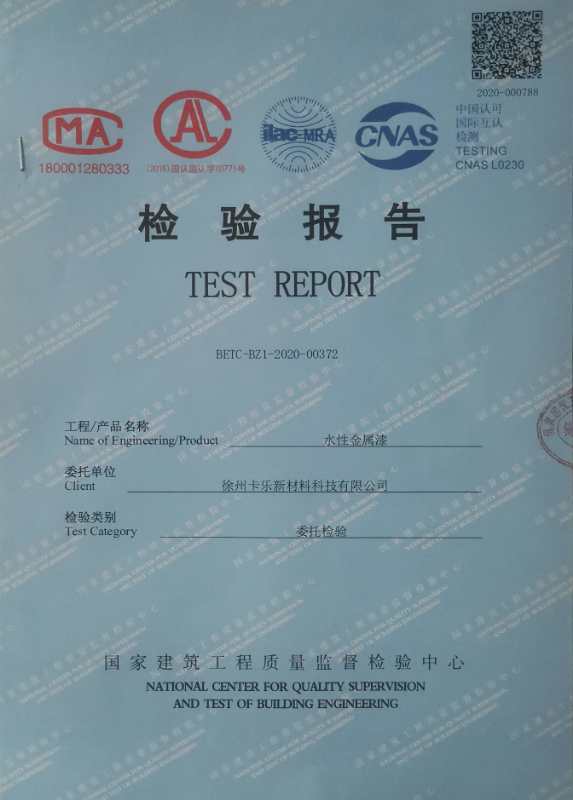

Adhesion (Hegelian) Papa 1

ʻO ka mālama pono ʻana o ka papa o ka mea i uhi ʻia me ka wai ʻole, ka aila, ke kalapona a me ka lehu.

Nā kikoʻī wikiwiki

ʻO ke kila me ka ʻili oxide: ʻO ka pana pana a i ʻole ke one puhi pahū e hana e like me ka hana ʻana i ka pae Sa2.5, kahi hiki ʻole ke hana i ka puhi one ʻana e pono e hoʻonani ʻia a me ka mīkini.

Mālama ʻia nā kemika e wehe i nā poʻohiwi haʻihaʻi āpau e lana ana.

ʻO ke kila me ka ʻili ʻole oxide: kahakaha (shotblasted) iā Sa2.5 a i ʻole hoʻoliʻiliʻi ʻia, nā mea hana wili uila i St3.

Hoʻopaʻa, ʻoki ʻana i ka lapalapaʻa a i ʻole hana hana ahi o nā wahi pana i kuni ʻia: wili i ka pae St3.

Nā mea i hoʻokumu ʻia me ke kiʻi ʻoniʻoni kahiko: hemo i nā ʻāpana pena kahiko a me ka popo, a me ke one i St3 me nā pono hana ʻili uila a uila paha.

Hiki ke hoʻohana ʻia nā pūʻulu pena maʻamau me ka H902 kumu hoʻokumu wai, a i ʻole hoʻohana ʻia wale ʻia ma ke ʻano he topcoat hoʻonaninani laulā, a hoʻohana ʻia paha me nā ʻano huahana primer (pono e hoʻohālikelike ʻia no ka hōʻoia ʻana).

Construction data Table dry (50% temperature) 15'C<th;25℃C<05h Actual dry (50% humidity) 15℃C<24h;25℃<12h Density about 1.1-1.20g/cm' Theoretical coating rate 0.15-0.2kg/m' (dry film 40-50) μm)

It is recommended to apply 2 coatings, which can be applied in the way of warm touching temperature to ensure that the dry film is 40-50μm.

To be sanded and finished with sandpaper.

Construction method Air or robot spraying is possible. Mix the paint before use, adjust the viscosity according to the construction method.

Add 5-15% of water. Add water and stir evenly, then leave the surface to work without bubbles.

Construction environment 1. The brain playground should have good ventilation and dust removal facilities to ensure the quality of construction.

2. The construction should be carried out under the condition that the mixing degree is above 5℃C and the relative humidity of the environment should be <70%.

3. The substrate temperature shall be not less than 5' and shall be more than 3'C above the air dew point temperature.

washout

| Vehicle Type | 100% Acrylic Latex | |

| COMPOSITION (nominal) | Pigment : Lightfast Non-Lead Pigments & Mineral Extenders.

Blinder : Acrylic Emulsion. Solvent : Water. |

|

| Volume Solids | 31.8% | |

| Coverage per Gallon at Recommended Film Thickness | 400 –450 Sq. Ft. (37-42 m2) | |

| Recommended Film Thickness

(Depending on surface texture and porosity. Be sure to estimate the right amount of paint for the job. This will ensure color uniformity and minimize the disposal of excess paint) |

Dry 1.2 mils

Wet 3.8 mils |

|

| Dry Time @ 77° F (25° C) @ 50% RH

(High humidity and cool temperatures will result in longer dry, recoat and service times.) |

To Touch 1 Hour

To Recoat 2 to 4 Hours |

|

| Dries By | Evaporation, Coalescence | |

| Viscosity | 99 ± 2 KU | |

| Gloss / Sheen | Flat (5-10 @ 85°) |

| Shipping time by Sea (Just for reference) | ||||||||

|

North America |

11~30 days | North Africa | 20~40 days | Europe | 22~45 days | South-east Asia | 7~10 days | |

| South America | 25~35 days | WestAfrica | 30~60 days | MiddleEast | 15~30 days | East Asia | 2~3 days | |

| Middle America | 20~35 days | EestAfrica | 23~30 days | Ocenia | 15~20 days | South Asia | 10~25 days | |

FAQ

1.About Sample

We provide free sample for testing.

2.OEM,ODM service available.

3.According to customer's request, packed with pallet or without pallet.

Tile adhesive(20kg/bag)packing with pallet specification:

64 bags/pallet = 1.28 MT/pallet

72 bags/pallet = 1.44 MT/pallet

One full 20ft container max loading 27.6MT.

With pallets can load 1360 bags, without pallet can load 1380 bags.